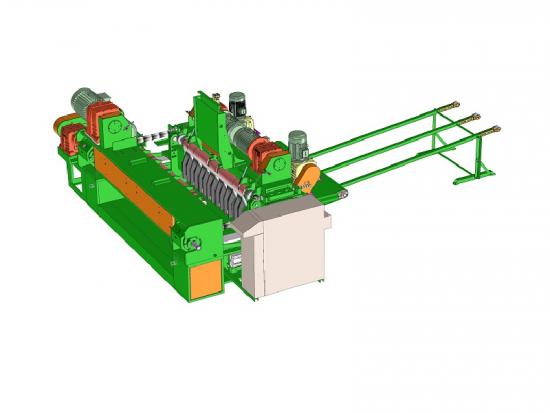

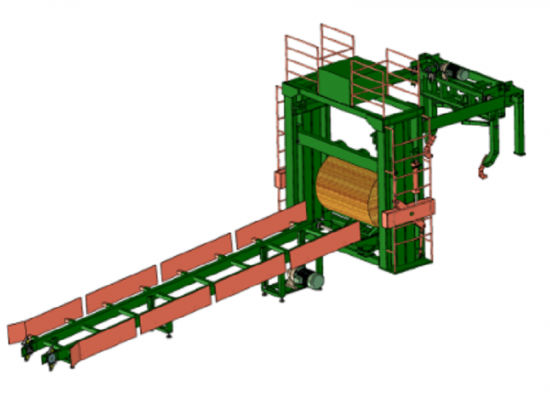

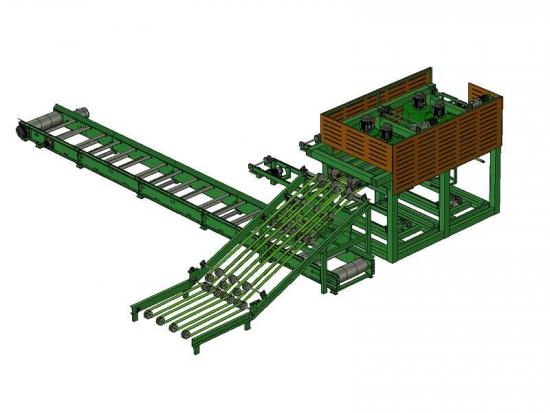

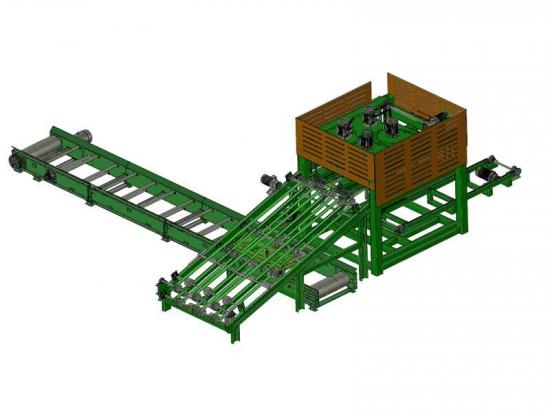

Product Name: 4*4 feet Mechanical Veneer Stacker

Major Technical Parameters

Stacking veneer width: 450-700 mm

Stacking veneer length: 960-1270 mm

Stacking veneer thickness : 1.7-4.0 mm

Stacking veneer height:0-1200mm

Stacking speed: 0-80m/min

Elevation way: Gearbox chain

Veneer stacking classification: 1,2 Grade

Veneer transfer type after stacking: Chain automatic transfer

Installed power: 7KW

Operating power:4.5kw

Total weight:1500kg

Overall Dimensions:9000*2800*2000