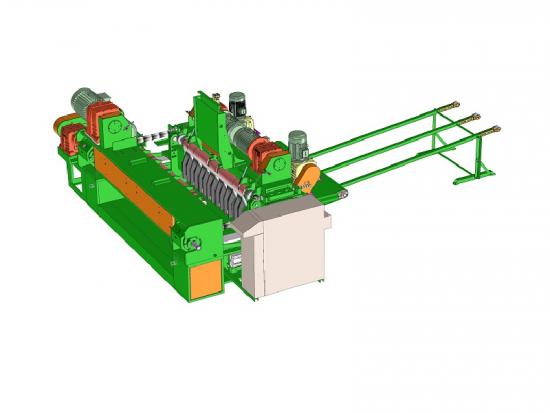

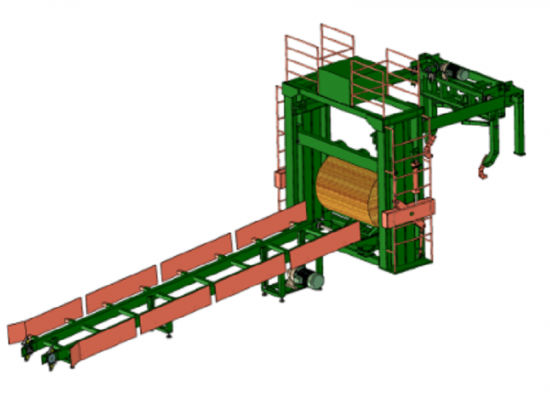

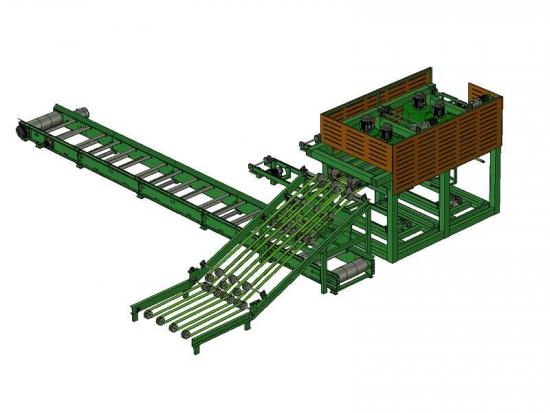

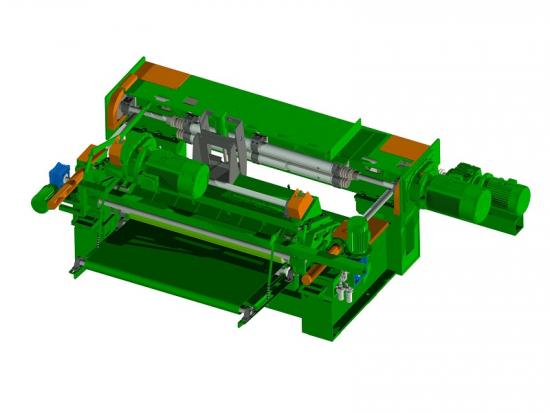

Product Name:Plywood hot press machine

Major Technical Parameters

Work layer: 15 layers

Pressboard dimension: 1370*2700*42/52mm

No. of pressboard: 16 pcs

Distance of pressboard: 73mm

Cylinder: φ400*2 φ125*1

Closing time: 15 S

Total power: 26kw

Total weight: 35000kg

Overall dimension 3400*1350*4300mm

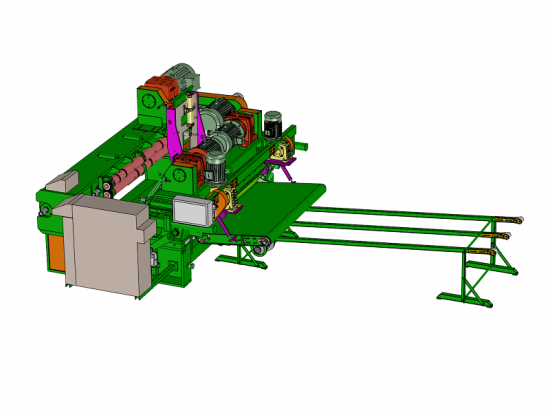

Main Features

- New designed frame, to ensure machine steady and use life.

- Auto temperature-controlled system, accept heat even.

-

With hydraulic system for high speed movement, saving time and raising producing ability.