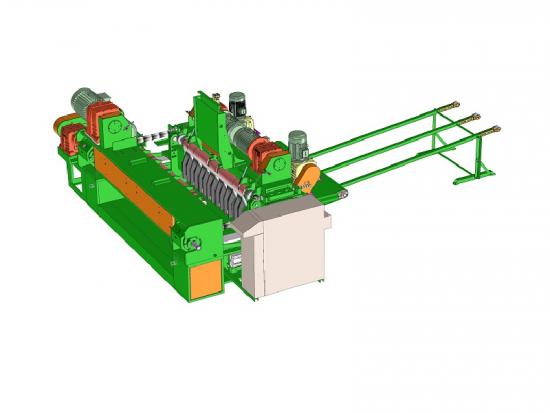

Product Name: 4ft Knife grinding machine

Major Technical Parameters

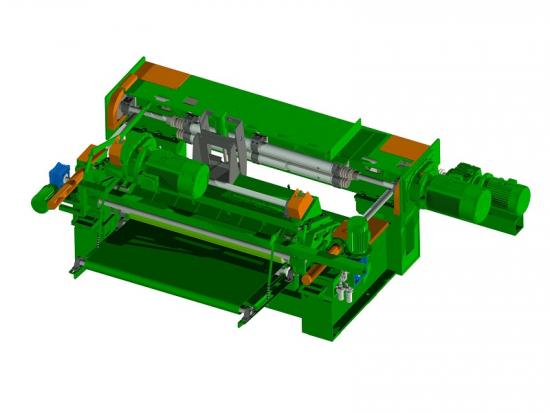

Model : BM1113/A

Longest grinding length: 1550mm

Width of worktable: Φ30-Φ400mm

Power of grinding head: 4kw

Linear speed of grinding wheel:15m/s

Speed of sliding plate: Step-less speed change

Titling range of the working table: +/-90°

Total Weight: 1980kg

Overall Dimensions: 3600*1400*1400

Main Features

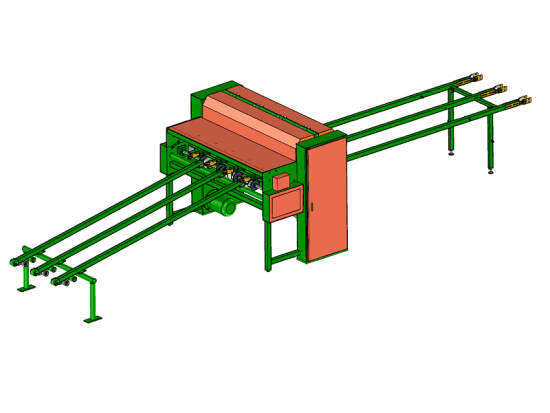

1.Knife grinder mainly grind all type of linear knives, like guillotine knives,slicer knife, peeling machine knife, Granulator knife, cutting paper knife and Shearing Blades.

2.This machine body is a design of gantry body, with the high-quality steel weld; stress relieved eliminating the internal stress. The body has high strength and good rigidity. No shrinking in centre of body.

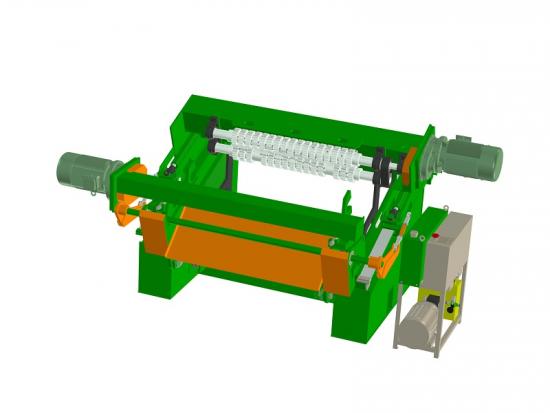

3.Job accuracy of machine is 0.01mm

4 The worktable is the electromagnetic chuck. It is very convenience to clamp knife. The worktable is easy to adjust the angle by worm gear. The width of the magnet is 180mm

5.The vertical movement of the grinding head adopts the ball screw, to ensure the accuracy.Also the type of vertical slide: Conventional

6.Converter motor is used for sliding plate; it is smooth in running and commutation freely.

Why Choose Us

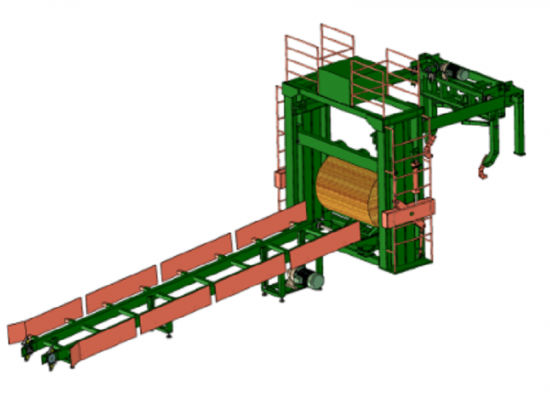

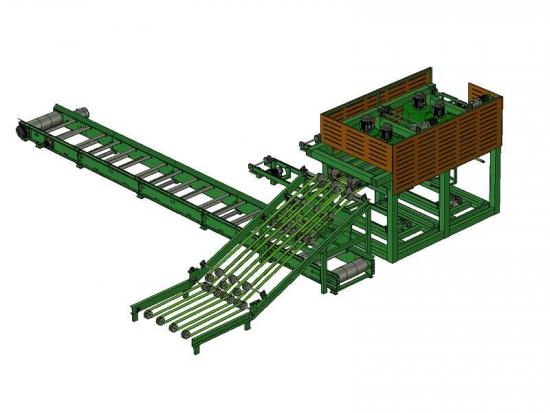

1. We are factory ofveneer peeling machine.

More than 20 years of experience in design and produceveneer peeling machine

Suitable price, good quality and best service

2. We provide best service

Pre-sale: provide the free consultation of the equipment.

During the sale: inspect the machine before leaving the factory.

After the sale:24 hours online services and send engineer for theveneer peeling machineinstallation