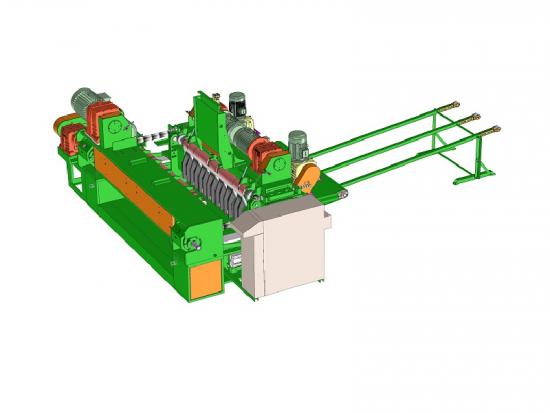

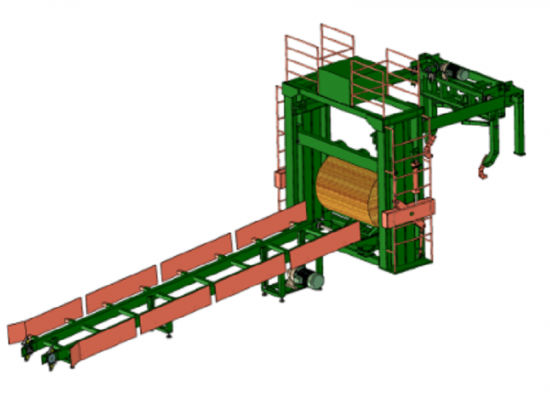

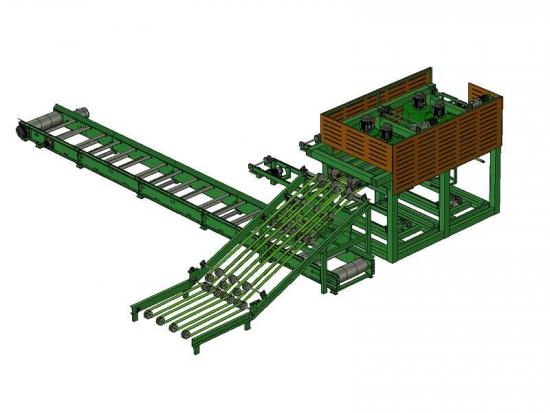

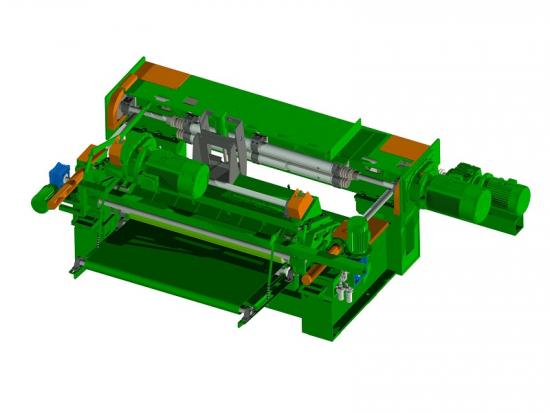

Product Name: Core veneer composing machine

Major Technical Parameters

DESCRIPTION

UNIT

Length of machine

mm

10000

Width of machine(the

widest point)

mm

2600

Width of machine(the

highest point)

mm

2600

Power of precursor

kw

3

Power of rear guard

kw

4.5

Power of front cutting

kw

3

Power of back cutting

kw

1.5

Power of conveyor 1

kw

1.5

Power of conveyor 2

kw

1.5

Power of elevating

kw

3

Power trunking

kw

4

Power of point-trough

kw

4

Length of knife

mm

1400

Effective width

mm

1350

Effective thickness

mm

1.2-3.5

Work efficiency

pcs/hour

250

Occupied area

mm

4000*14000

Total weight

kg

5500

Main Features

Core veneer composing machine mainly used in horizontal splicing 2 or more pcs venner with same thickness joint to one wood veneer sheet.This machine can automatic stack veneer . It won’t stuck and overlap the veneers while working. And the glue thread can stick tightly.