|

ITEM NO. |

DESCRIPTION |

UNIT |

SPECIFICATION |

SPECIFICATION |

|

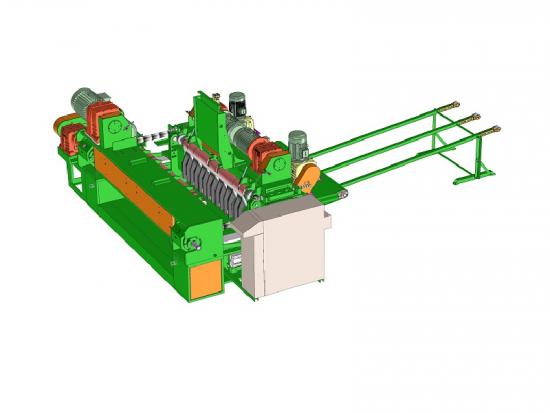

01 |

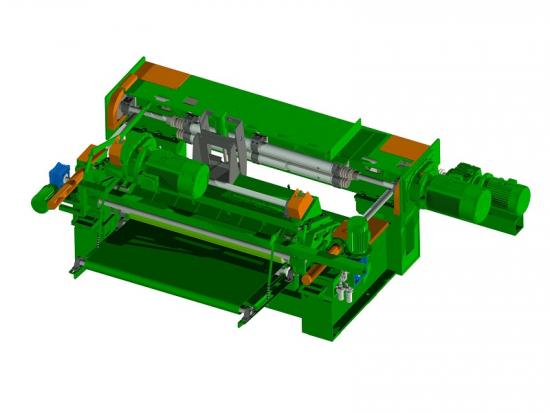

Control system type |

/ |

PLC/ Servo |

PLC/ Servo |

|

02 |

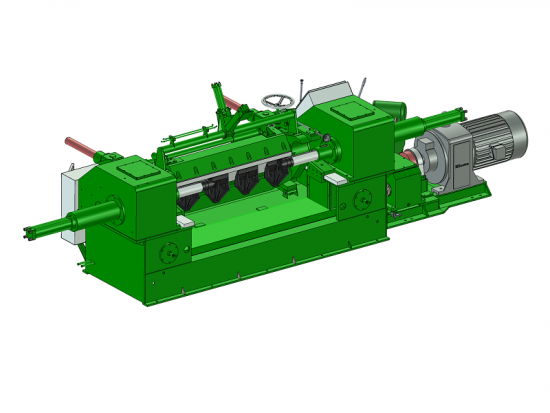

Cutting length |

mm |

2440-2460 |

1830-2460(adjustable) |

|

03 |

Cutting width |

mm |

1220-1240 |

900-1240(adjustable) |

|

04 |

Cutting thickness |

mm |

10-60 |

10-60 |

|

05 |

Saw blade size |

mm |

Φ180/φ305 |

Φ180/φ305 |

|

06 |

Vertical sawing speed |

m/min |

30-60m/min |

30-60m/min |

|

07 |

Horizontal sawing speed |

m/min |

30-60m/min |

30-60m/min |

|

08 |

Motor power |

kw |

37 |

37 |

|

09 |

Application |

/ |

Plywood, MDF, Particle board etc. |

Plywood, MDF, Particle board etc. |

|

10 |

Working style |

/ |

Infrared ray guidance |

Infrared ray guidance |

|

11 |

Weight |

kg |

5000kg |

5000kg |

|

12 |

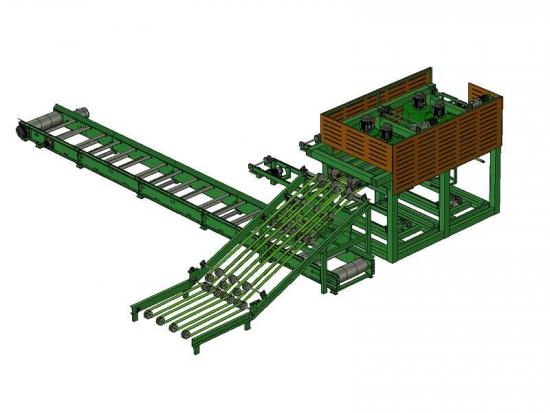

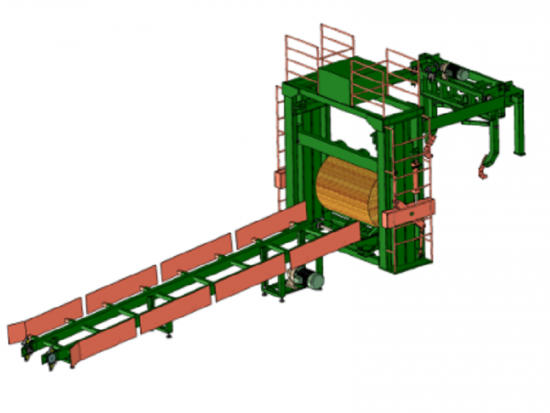

Feeding way |

/ |

Manual/Full automatic |

Manual/Full automatic |

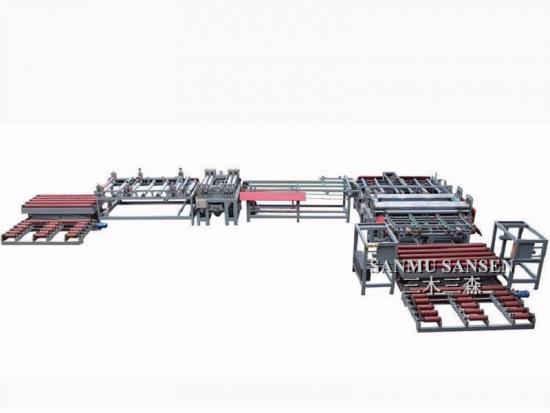

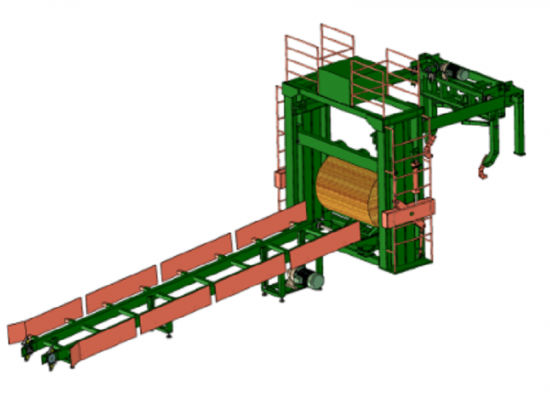

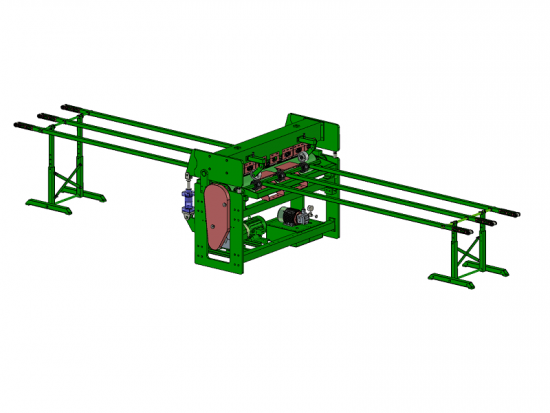

Features

1. The machine frame and rail is produced by planning machine, which guarantee the accuracy of the machine.

2. Automatic lifting pusher and transfer platform increase the output of plywood trimming.

3. Double saw blade of saw head will prevent burrs on the board edge area.

4. The wide saw design technology prevents dust and improves the service lift of the cylindrical guide.