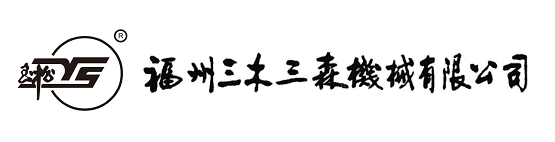

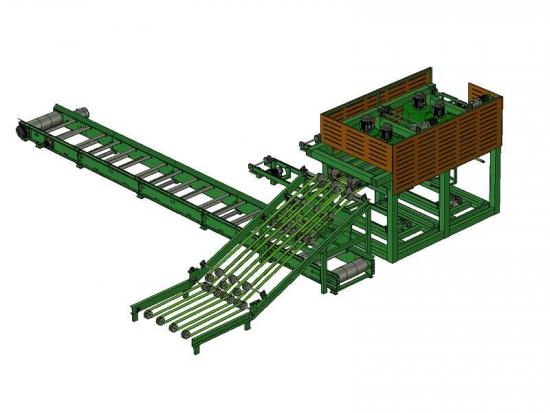

Product Name: 4ft Veneer Stacking Machine

Major Technical Parameters

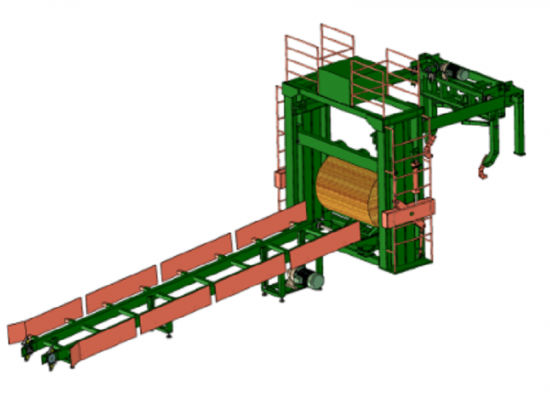

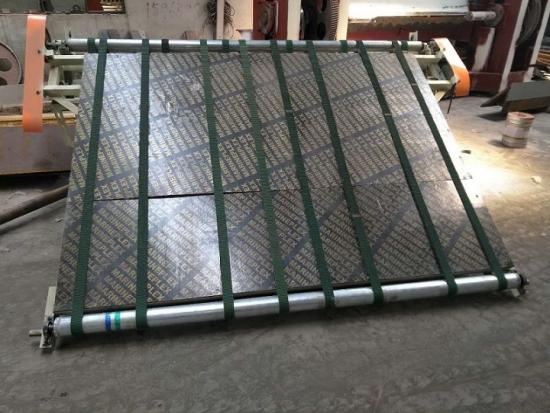

Stacking veneer width: 1270(1300)

Stacking veneer length: 500-900-1270mm

Stacking veneer thickness : 1.5-3.6 mm

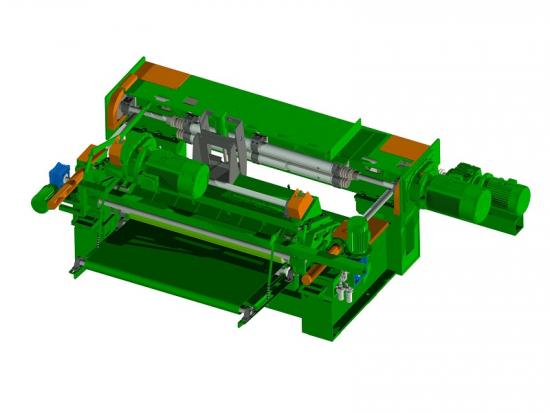

Elevation way: Hydraulic lift

Veneer stacking classification: 1,2

Veneer transfer type after stacking: Chain automatic transfer

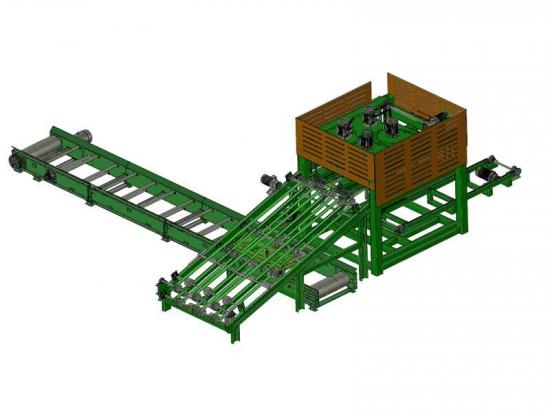

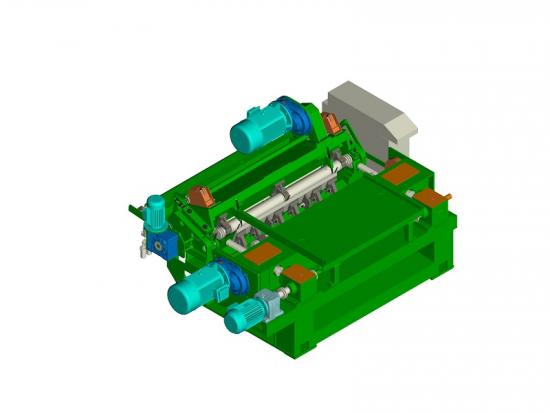

Air blower specification and number: 1.5KW*4

Air blower: Inverter

Total power:15.25KW

Overall Dimensions:14000*1400

Features:

1 .Labor Saving

2. High efficiency

3. Customize is available

4. Adapt to different veneer and plywood manufacture

5. A user-friendly structure helps the operators spot any problems.

( Design production line or link with your own production)