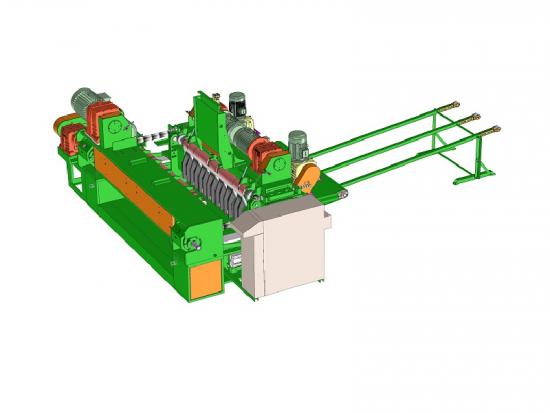

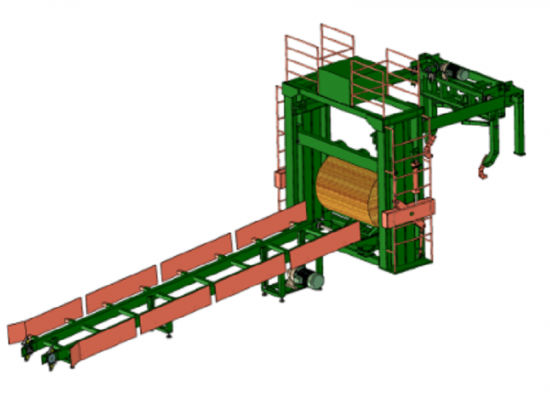

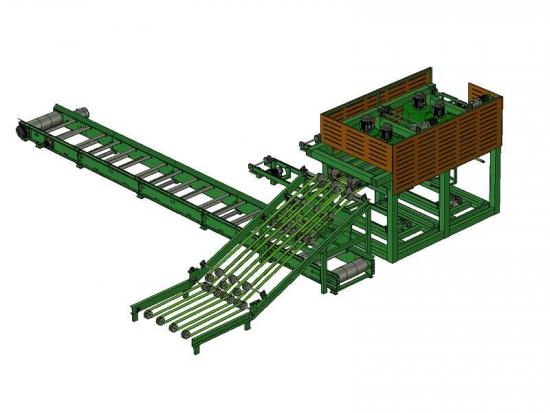

Production name: Plywood core veneer patcher

DESCRIPTION

UNIT

Pressure range

MPa

0.6-0.95MPa

Rated power

KW

小于 0.1KW

Working pressure

/

AC220V-50Hz

Max working thickness

mm

≤2.6mm

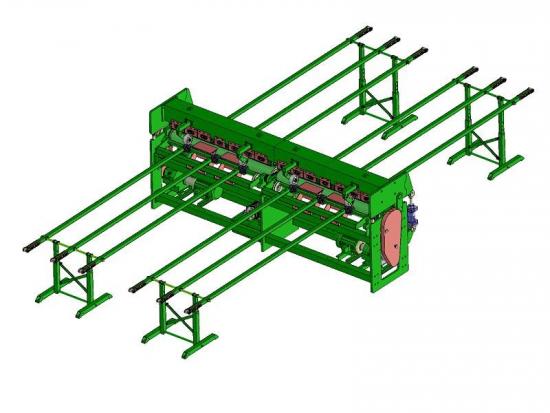

Veneer cutting length

mm

2600mm

Veneer cutting width

mm

1300mm

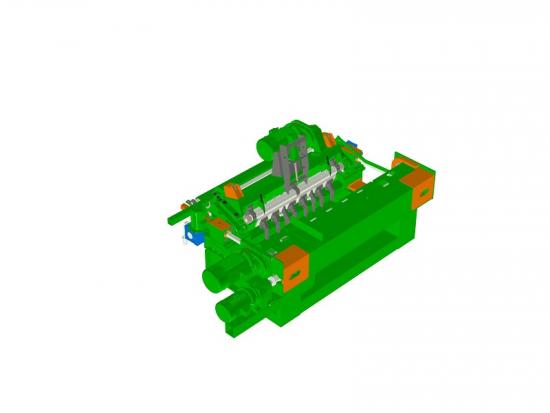

Mold size

mm

500*200/350*160/150*80mm

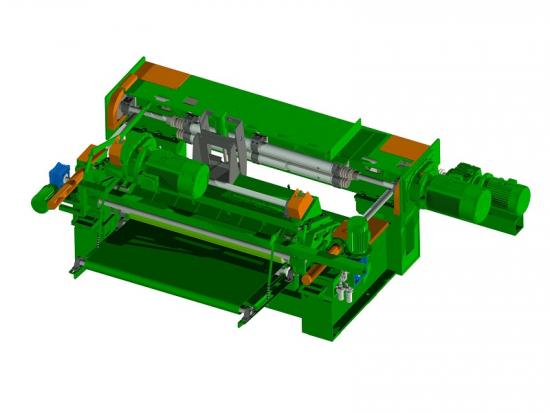

Main machine dimension

mm

3450*1250*1600mm

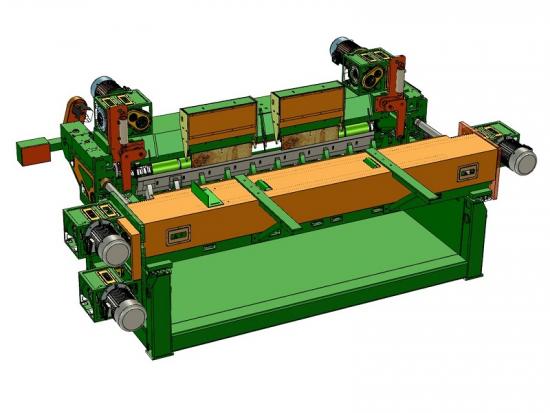

Working platform dimension

mm

3000*3355mm

Weight

KG

1500KG

Features:

2. Comparing with traditional manual veneer fixing way, this machine has more easy operation.

3. The defected wood veneer after mending looks more smooth and beautiful.