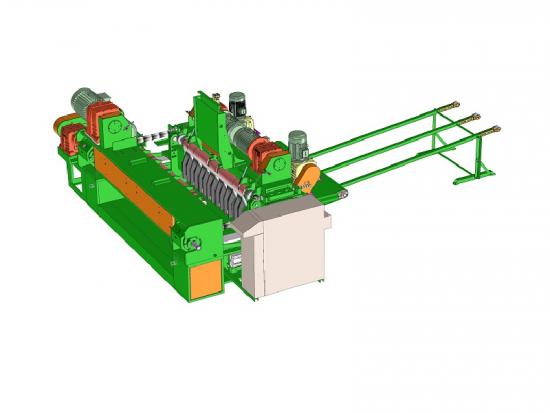

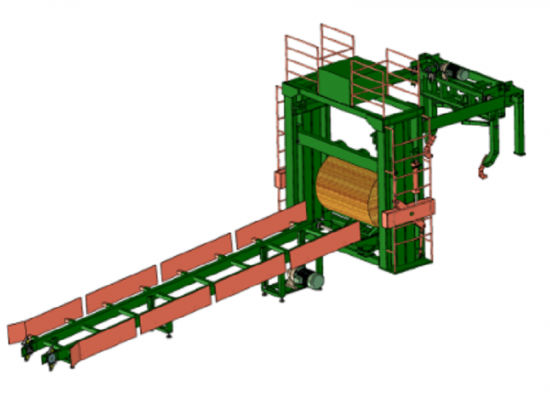

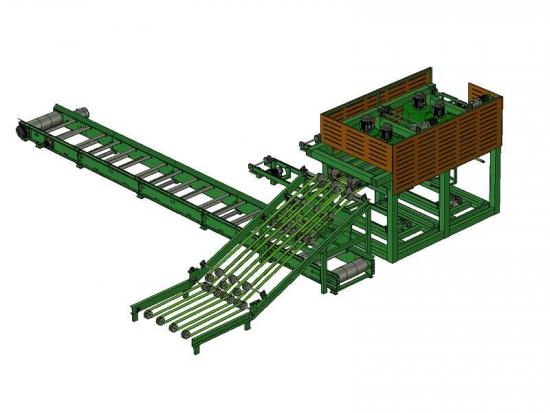

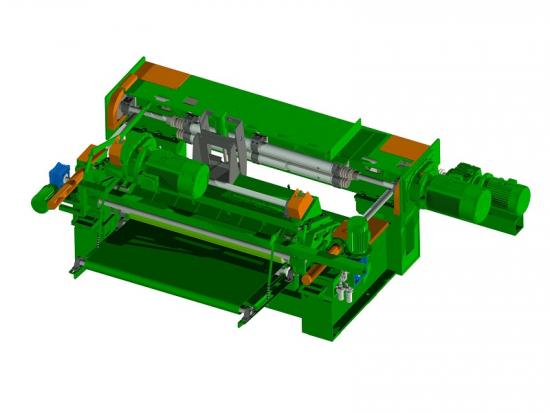

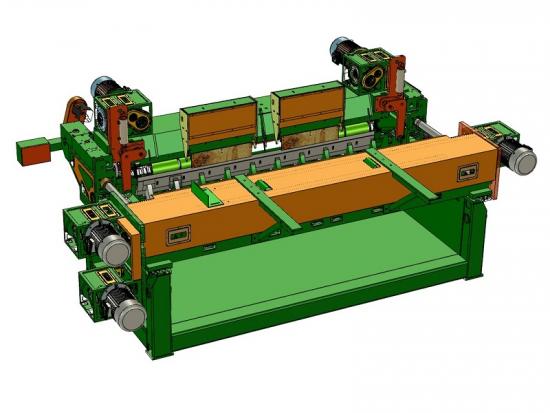

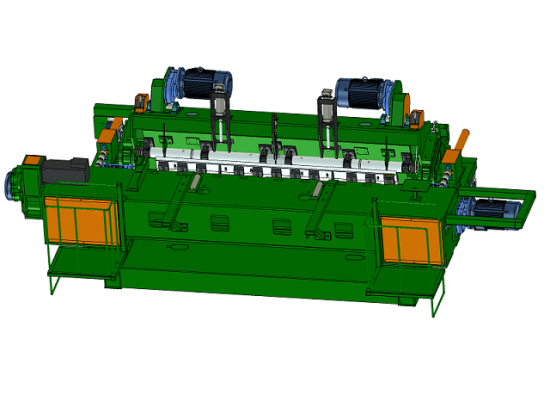

Production name:Automatic plywood core veneer patching machine

|

修补单板尺寸(蝶形) Mending veneer size(Butterfly model) |

40×60 mm |

60×100 mm |

75×130 mm |

90×150 mm |

|

修补单板厚度(mm) Mending veneer thickness |

0.8~3 |

|||

|

修补速度 Mending speed |

约3~5 s/次(Each process takes about 3~5 seconds.) |

|||

|

电机功率(KW) Power |

4.25 |

4.25 |

6.05 |

6.05 |

|

压缩空气(kg/cm2) Compressed air |

4~6 |

|||

|

额定油压(MPa) Normal oil pressure |

16 |

16 |

16 |

16 |

|

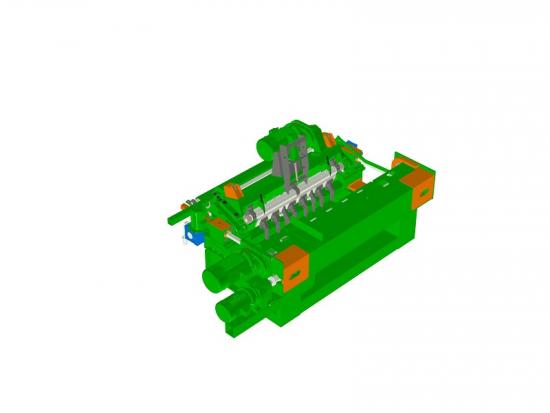

油缸直径(mm) Diameter of cylinder |

Φ50 |

Φ63 |

Φ80 |

Φ80 |

|

外形尺寸(长×宽×高)(mm) Overall dimension |

1795×1300×1750 |

1795×1300×1750 |

1810×1500×1750 |

1810×1500×1750 |

|

重量(kg) Approx weight |

1200 |

1200 |

1500 |

1500 |

Features:

2. Comparing with traditional manual veneer fixing way, this machine has more easy operation.

3. The defected wood veneer after mending looks more smooth and beautiful.